Ingot

Our process begins with the selection of premium-grade aluminium ingots. These solid blocks of pure aluminium are the starting point for all our products. The quality of these ingots is crucial as it directly impacts the strength, durability, and overall quality of the final extrusion.

Melting

The aluminium ingots are then placed into our advanced furnaces, where they are heated to their melting point. This step is essential for transforming the solid ingots into a molten state, allowing us to create a consistent aluminium alloy that can be further processed. The temperature is carefully controlled to ensure the alloy’s purity and uniformity.

Billets

Once the aluminium is fully melted, it is cast into billets—cylindrical blocks that serve as the raw material for the extrusion process. These billets are cooled under controlled conditions to ensure they maintain the necessary structural integrity for the extrusion process. Each billet is inspected for any impurities or defects before moving to the next stage.

Moulding

Before extrusion, the billets are preheated to a specific temperature to ensure they are malleable but not molten. The preheated billet is then placed into an extrusion press, where it is forced through a die—a steel tool designed to shape the aluminium into the required profile. The die’s design is crucial as it determines the cross-sectional shape of the final product, whether it’s a simple or complex profile.

Extrusion

During the extrusion process, the preheated billet is pushed through the die using a powerful hydraulic press. As the aluminium is forced through, it takes on the shape of the die’s cross-section, emerging as a continuous length of the desired profile. This process requires precise control to maintain the correct temperature, pressure, and speed, ensuring a consistent and accurate final product.

Ageing

After extrusion, the profiles undergo an ageing process, where they are heated in a controlled environment to a specific temperature. This heat treatment enhances the mechanical properties of the aluminium, such as strength and hardness, ensuring the extrusions are robust and durable for their intended applications. The ageing process is meticulously timed and monitored to achieve the desired material properties.

Polishing

To achieve a smooth and aesthetically pleasing finish, the extruded profiles are subjected to a polishing process. This step involves mechanically or chemically treating the surface to remove any imperfections, such as rough edges or marks left by the extrusion process. Polishing also prepares the aluminium for subsequent surface treatments, ensuring a high-quality finish.

Powder Coating

For added protection and enhanced appearance, the polished profiles undergo powder coating. In this step, a dry powder made of pigment and resin is electrostatically applied to the surface of the aluminium. The coated profiles are then cured in an oven, where the powder melts and forms a tough, protective layer. Powder coating not only provides a durable finish that resists corrosion and wear but also allows for a wide range of colours and finishes, tailored to the client’s needs.

Quality Control

Quality control is an integral part of our process. Throughout production, we perform rigorous inspections at each stage to ensure that every profile meets our strict quality standards. This includes checking dimensions, surface quality, and structural integrity to ensure that each extrusion complies with the specified requirements.

Testing

In addition to routine quality checks, the extrusions undergo comprehensive testing to verify their performance characteristics. This may include tensile strength tests, hardness tests, and other mechanical evaluations to confirm that the extrusions meet the required specifications and industry standards. These tests are crucial for ensuring that the products will perform reliably in their intended applications.

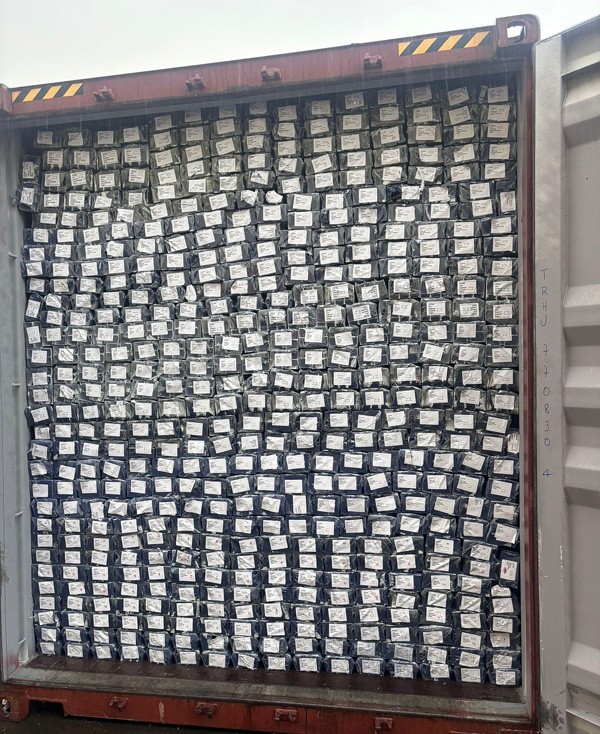

Container

Once the extrusions have passed all quality checks and tests, they are carefully packed into containers for transportation. Proper packaging is essential to protect the profiles from damage during transit. We use appropriate packing materials and techniques to ensure that the products are secure and arrive in perfect condition at their destination.

Delivery

Finally, the finished and packaged products are delivered to our clients. We coordinate logistics to ensure timely delivery, whether it’s a local shipment or an international order. Our focus is on making sure that the products arrive safely and on time, ready for immediate use in your projects.